3D printers that print with concrete from trusted manufacturers

A finished house in 48 hours is already a reality

Construction Opportunities

3D concrete printing technology can be easily integrated into your construction processes, giving you new competitive advantages.

Minimizes costs

Special software allows you to reduce the amount of concrete used, labor hours, and material transportation costs.

Strength and quality

Certified ecological mix for strong concrete of D30 brand in Ukraine meets all international standards.

Construction speed

On an industrial scale, printing a 100 m² house with finishing takes only 30 hours and is 20% cheaper than a conventional gas block.

7 Steps to a Finished Home

Take the finished architectural project

Classic architectural projects are developed in special applications that our software understands well.

Upload to Slicer - it's our digital assistant

The program automatically decomposes the plan into horizontal stages of layer-by-layer printing, taking into account the type of wall (load-bearing/non-load-bearing), its width and thickness, and the distances between them. This allows you to geometrically accurately apply layer after layer of concrete mixture.

Calculate the costs of the mix

After creating a model for 3D printing, the program gives the amount of construction mix required for the project. At this stage, you can also see possible thermal bridges and avoid them.

Click the button, start printing the house

Of course, before starting printing, it is advisable to prepare the area where printing will take place 😉

We monitor the printing, install communications, ventilation ducts, and carry out reinforcement.

Machine vision is used for printing, but the presence of a person at the site must be ensured. Communications are mounted between two layers of walls, and the holes for them are laid during printing, which means that there is no need to drill and chip the walls additionally, which reduces the cost and time. Reinforcement is done by inserting a reinforcing cage between the walls or reinforcing elements between the layers during the printing process, as required by the technical specifications.

We install windows and doors

We are preparing to put it into operation

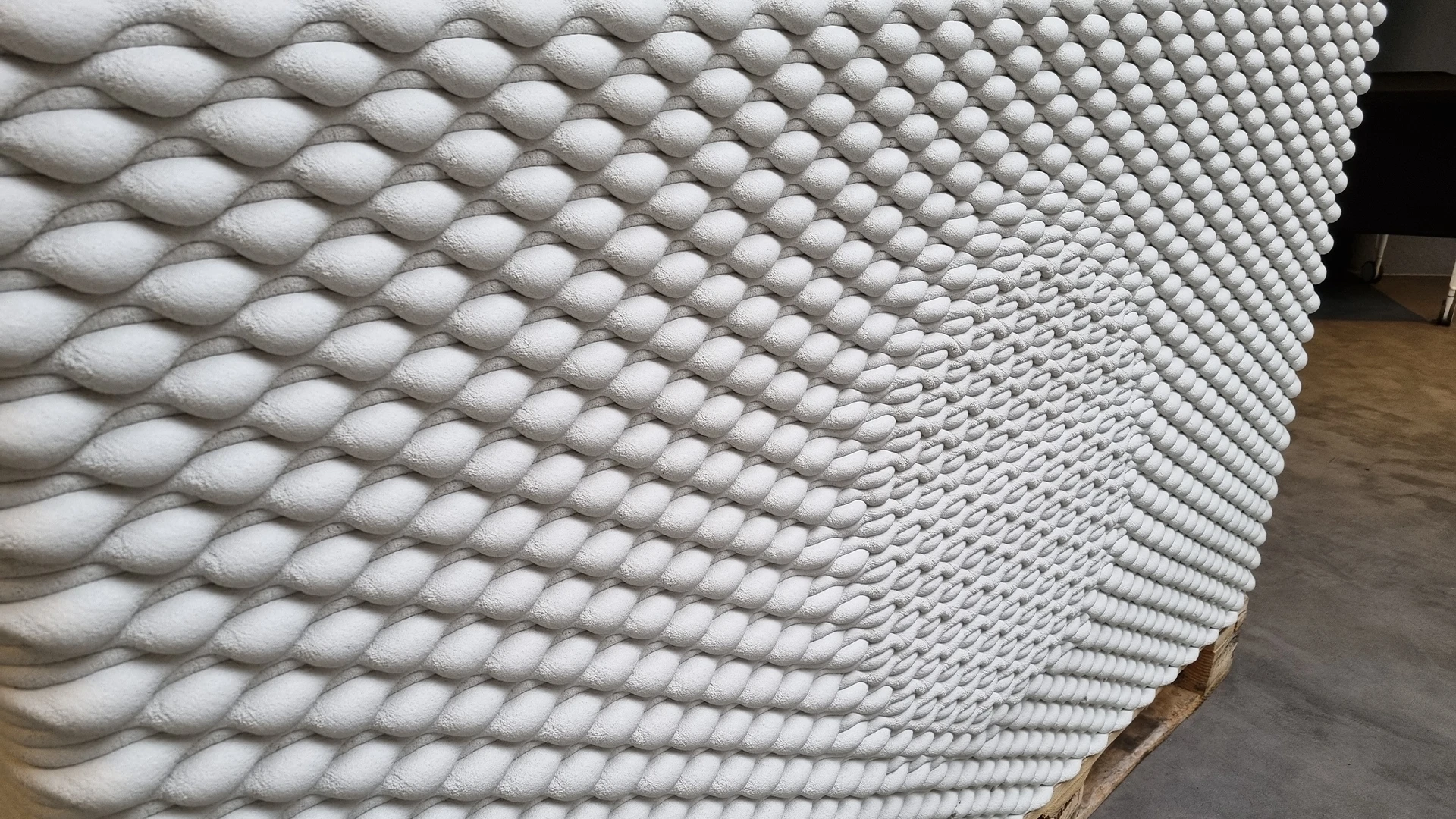

Walls

Concrete walls printed using a 3D printer are highly durable and reliable, which ensures their durability and resistance to various weather conditions.

Wall 1 layer

- Layer thickness 40 mm

- Extrusion weight 100 kg/m²

Wall 2 layers

- Layer thickness 80 mm

- Extrusion weight 200 kg/m²

- Possibility of using internal insulation

Roof or wall in 3 layers

- Layer thickness 120 mm

- Extrusion weight 340 kg/m²

- Number of straight layers 2

- Number of wavy layers 1

- Possibility of using internal insulation

Wall in 4 layers

- Total thickness 500 mm

- Layer thickness 160 mm

- Insulation thickness 200 mm

- Void thickness 140 mm

- Extrusion weight 440 kg/m²

- Number of straight layers 3

- Number of wavy layers 1

Freedom in architecture

Free design and implementation of non-standard structures. 3D concrete printing is not just about printing houses.

3D printing technology makes it possible to create a variety of architectural forms that would be difficult or even impossible to realize using traditional construction methods. In addition, this technology can significantly reduce the time and minimize errors in their manufacture.

- Staircase

- Ventilation shafts

- Building Blocks

- Defensive structures

- Fences

- Custom Walls

- Garden decorative elements

- Even fireplaces

- Anything invented by man can be realized in concrete

Benefits of our offer

Stable pricing strategy for 12 months from the manufacturer.

Fixed contractual cost of the mixture from the manufacturer for 12 months, which minimizes the risk of force majeure with prices and miscalculations.

Government Grant

Opportunity to receive a government grant for a processing plant and purchase a 3D printer with government funding.

Job Creation Funds

Grant funds do not need to be repaid if you create jobs.

Protection against wartime losses

The state guarantees the reimbursement of your contribution in case of destruction of equipment during military operations and removes all obligations.

Printer models

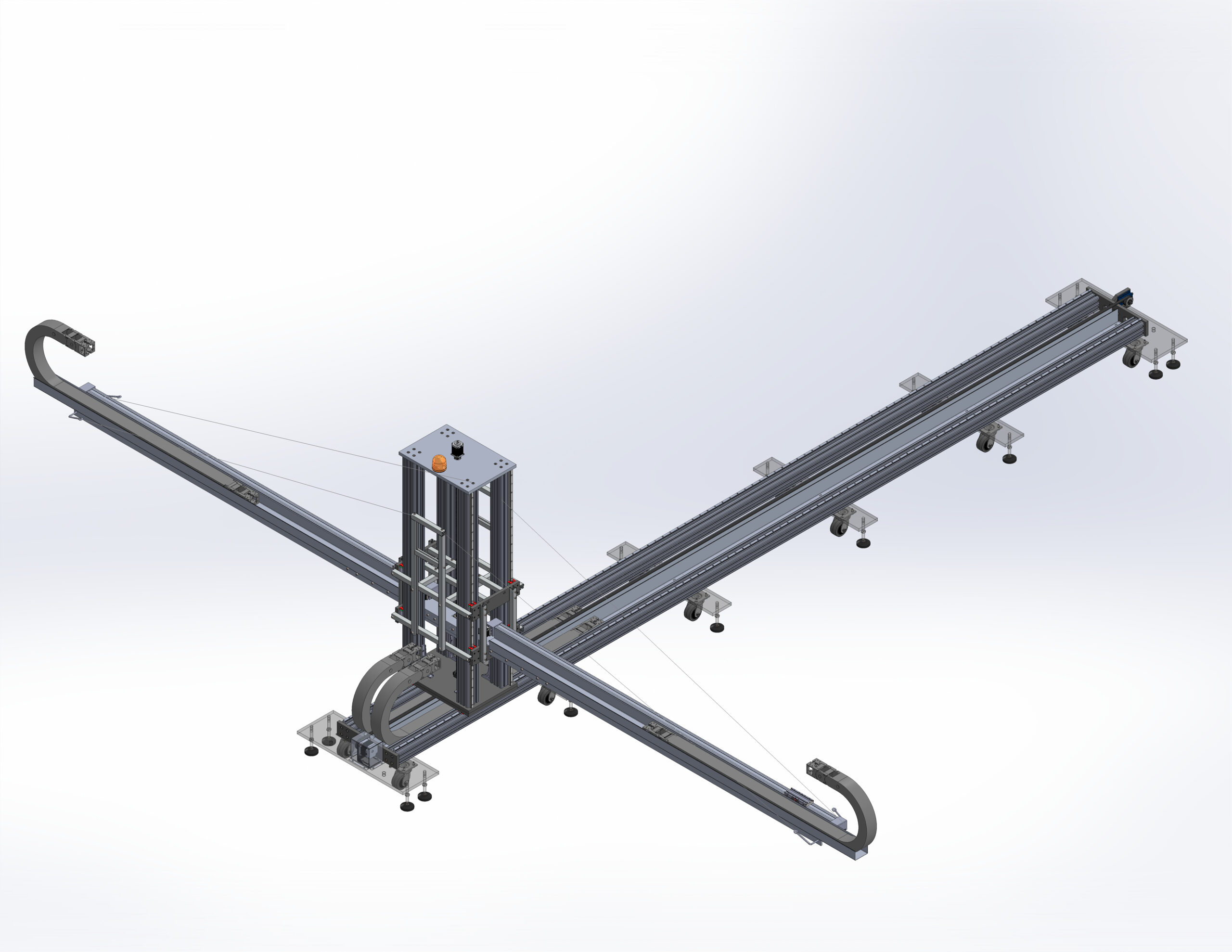

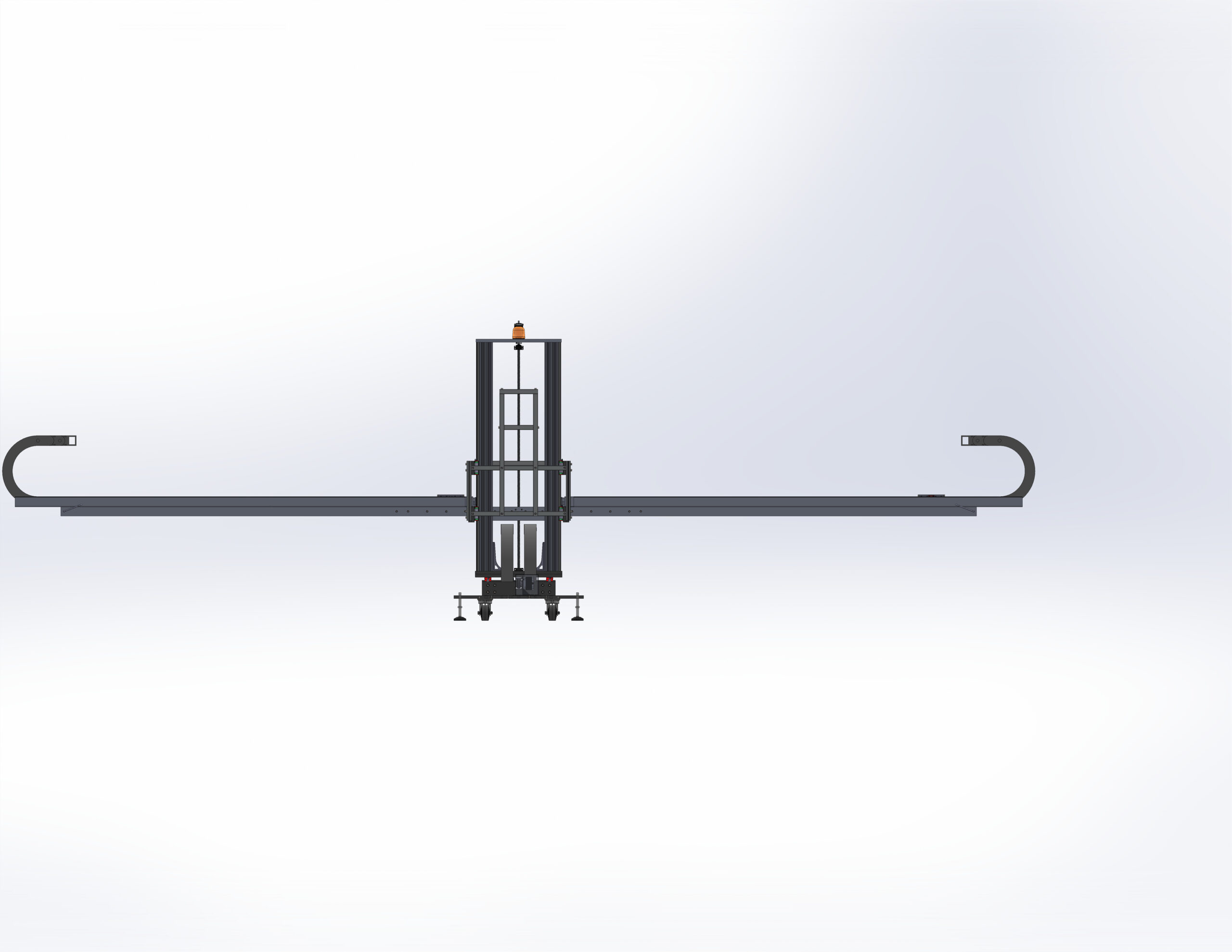

Construction 3D printer of portal type

Printer weight

2000 kgPrinter height

2200 mmPrint height of the printer

1200 mmPrint field size

10 000 x 5000 mmFeeding system

Peristaltic pump (Possibility to work without a pump, manual feeding into the hopper)Power consumption

360 V, up to 2 kWh, without pumpPrint speed

150 mm/secConstruction 3D printer lifting radial

Printer weight

1800 kgFolded dimensions (length, width, height)

4500 mm x 1200 mm x 1600 mmMaximum height (when raised)

3500 mmMaximum boom extension length (from the center)

3500 mmDiameter of the printable area

14000 mmManeuverability

Autonomy, it is possible to work directly on the object, it can be additionally equipped with a mobile mechanism on tracksFeeding system

Peristaltic pumpElectricity supply

360 V, up to 6.5 kWhPrint speed

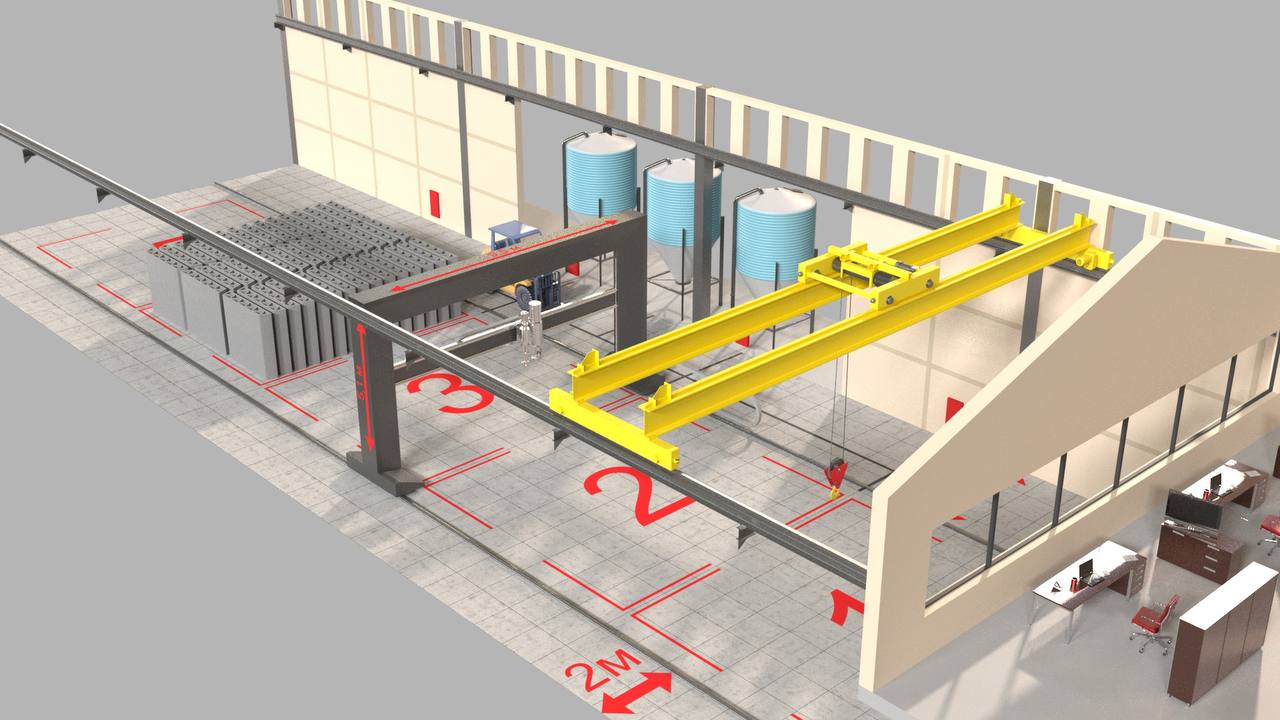

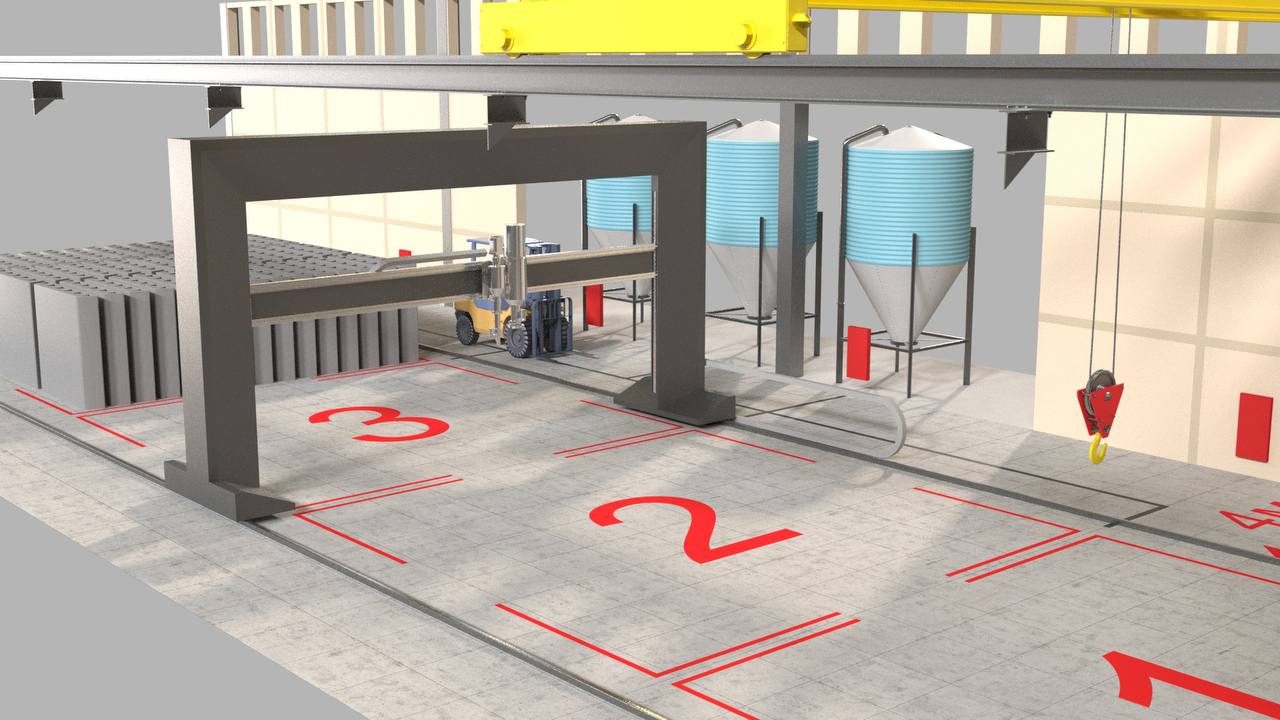

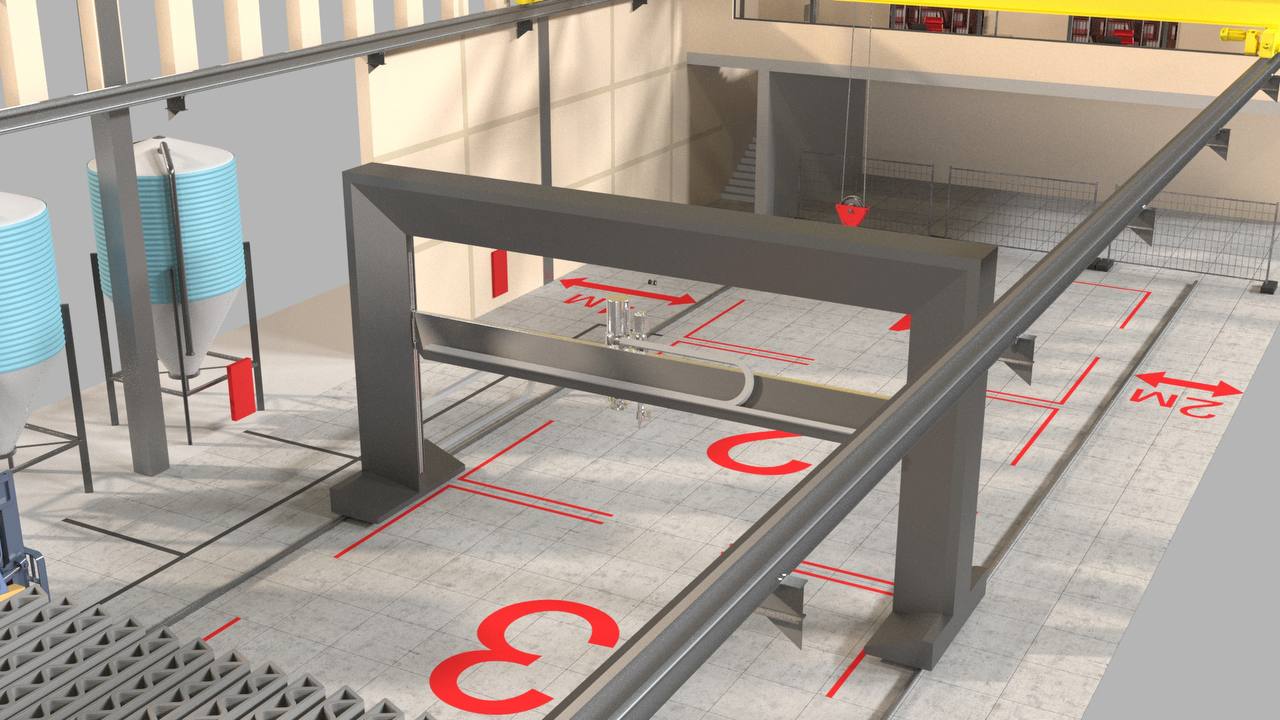

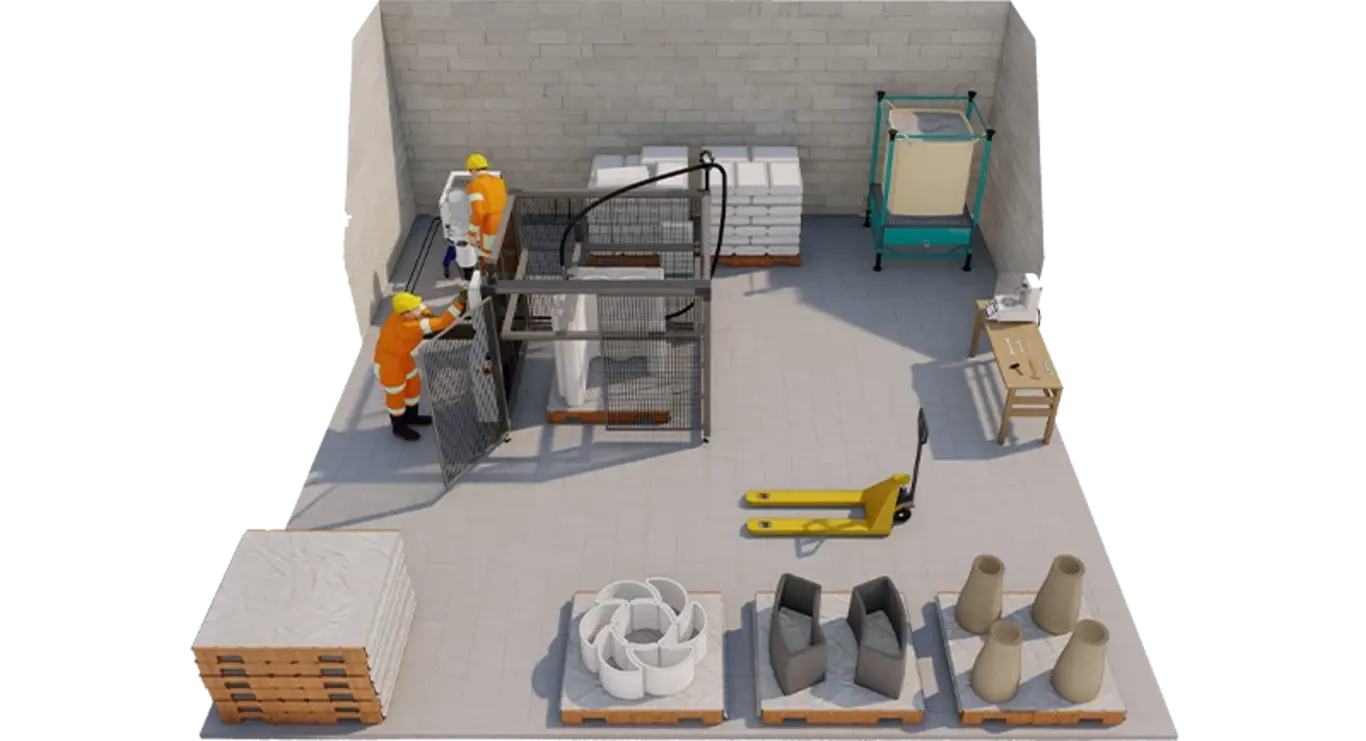

150 mm/secFactory for the production of prefabricated houses and modular structures, the principle of operation is a portal 3D printer

Printable field dimensions (length, width, height)

24 000 mm x 7500 mm x 3500 mmFeeding system

Peristaltic pumpElectricity supply

AC 360V, up to 20 kWhPrint speed

300 mm/secAdvantages

A full-fledged factory for the production of prefabricated houses and modular structuresAutomated mix and water supplyAutomated concrete batching plantAvailable 24/7/365Prints a finished house in 48 hoursConstruction 3D printer how it works SCARA

Printer weight

1200 kgPrinter height

4300 mmPrint height of the printer

3300 mmDiameter of the printable area

14000 mmFeeding system

Peristaltic pumpManeuverability

Autonomy, it is possible to work directly on sitePower consumption

360 V, up to 7 kWhSpeed of movement

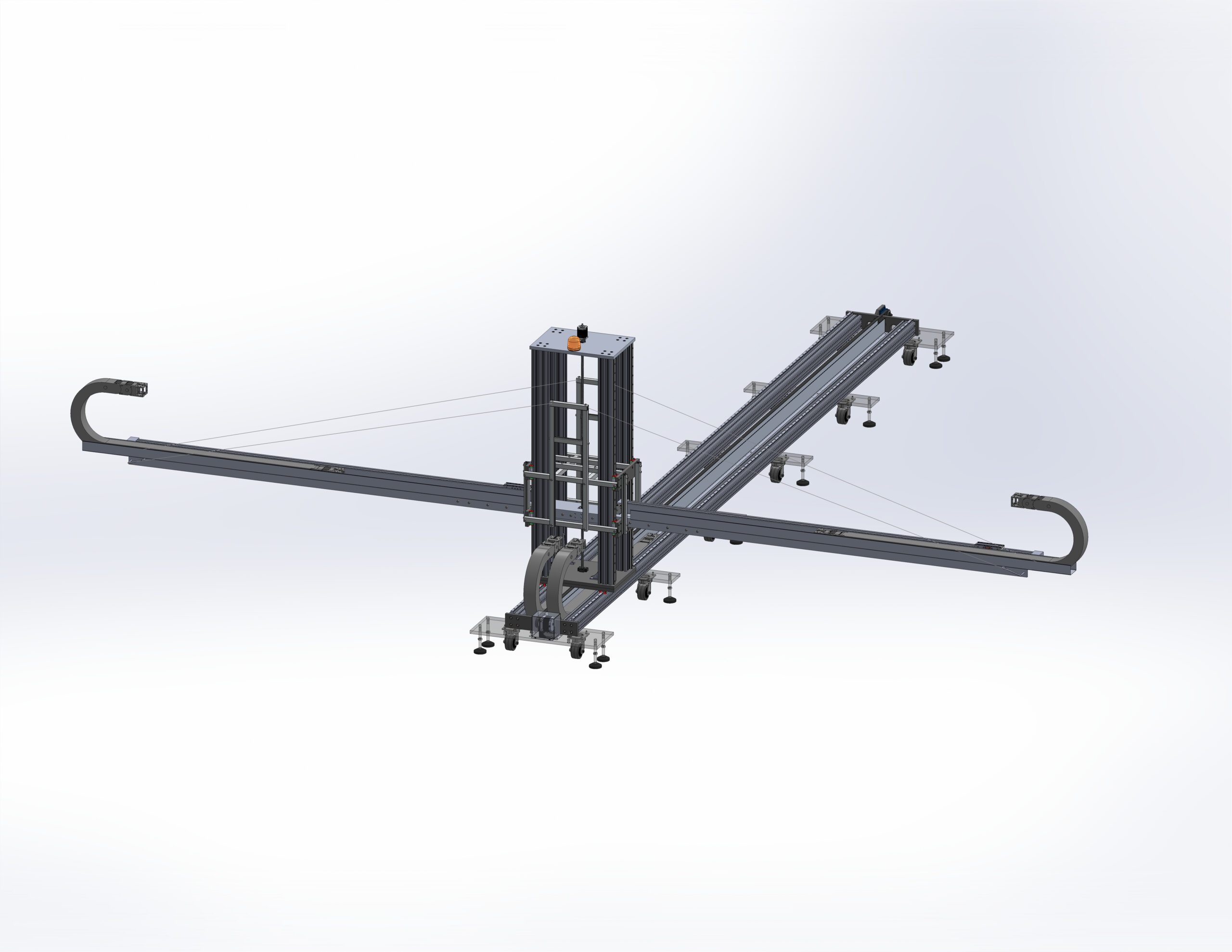

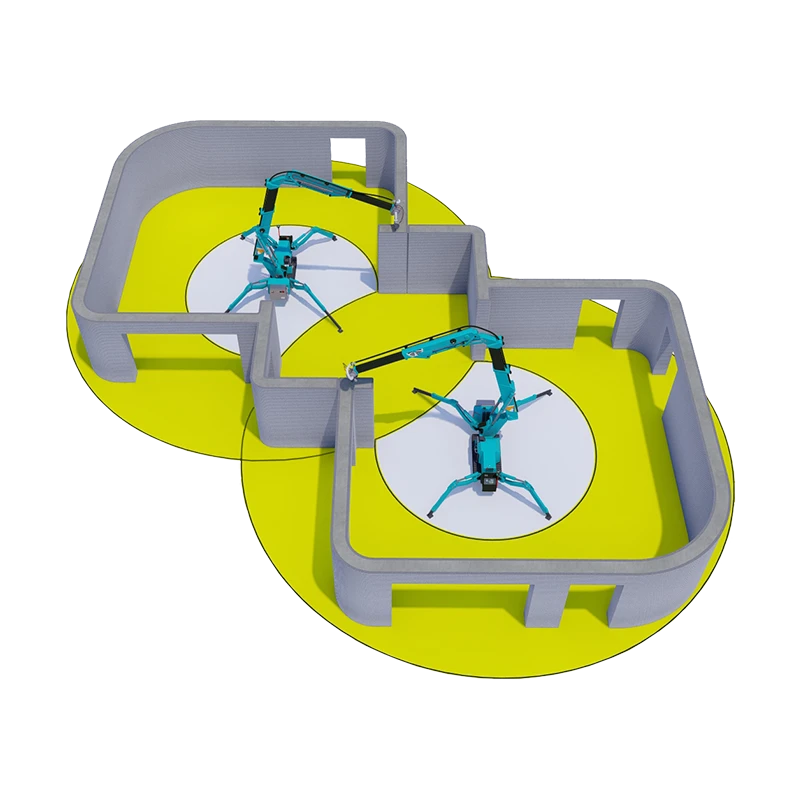

120 mm/secConstruction 3D printer with simultaneous printing on both fields

Printer weight

800 kgPrinter height

2200 mmPrint height of the printer

1250 mmPrint field size

2500 mm x 6000 mm x 2 fieldsFeeding system

Peristaltic pumpManeuverability

Prefabricated, mobile design, it is possible to work directly on sitePower consumption

360 V, 5 kWhPrint speed

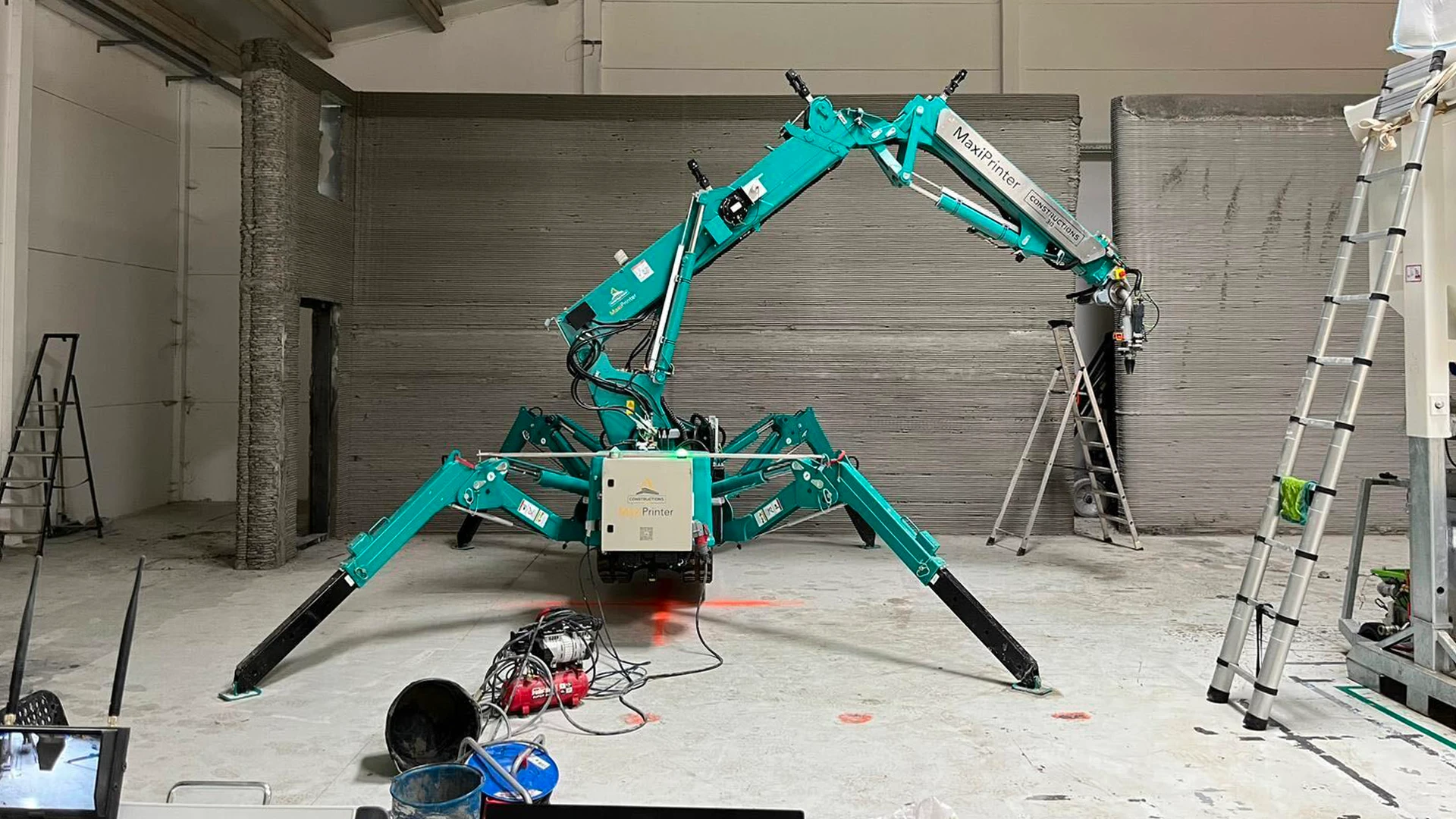

300 mm/secMaxiPrinter Fast, mobile and compact 3D printer for concrete

Print speed

250 mm/secElectricity, kWh

10Print field size

12 500 mm x 12 500 mmPrinter height

1 990 mmPrint height of the printer

3 850 mmFeeding system

Protowa automatic mixing stationPrinter weight

2 700 kgPersonnel per shift

3Extrusion

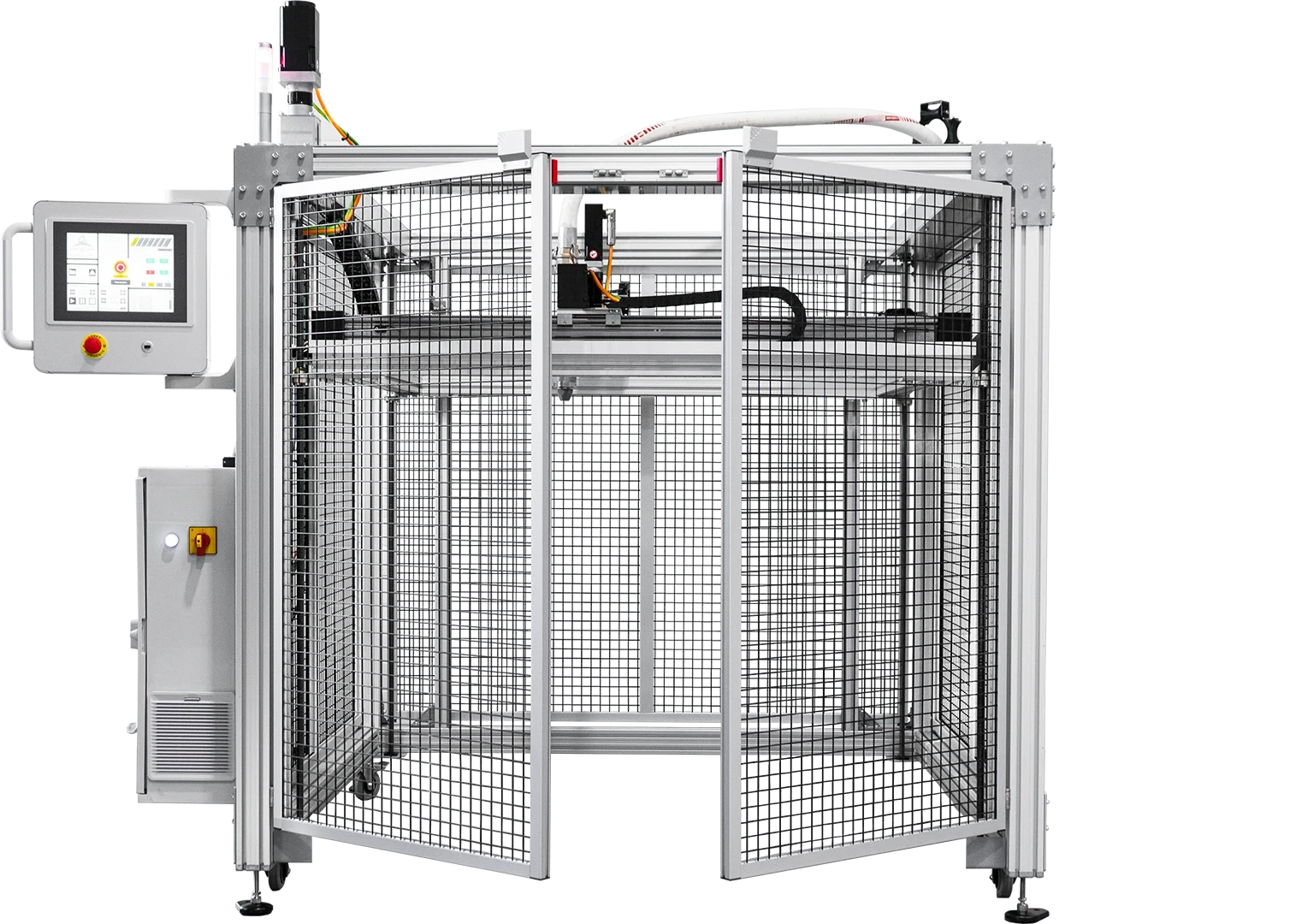

10 000 kg/dayMiniPrinter PRO Productivity, simplicity

Print speed

400 mm/secElectricity, kWh

10Print field size

1 200 mm x 1 200 mm x 1 200 mm / 2 400 mm x 1 200 mm x 1 200 mmFeeding system

Protowa automatyczna mieszarkaPrinter weight

2 700 kgPersonnel per shift

3Extrusion

10 000 kg/day3D printer for the production of special fences Craftruder

Print speed

300 mm/secElectricity, kWh

10Print field size

41 000 x 4000 mmPrinter height

1800 mmPrint height of the printer

500 mmFeeding system

ScrewMaximum extrusion fraction

< 11 mmProductivity

10 m²/hourConstruction 3D printer, portal type Q-Frame mini 463

Print speed

150 mm/secPrint field size

4000 mm x 6000 mmElectricity, kWh

7Print height of the printer

3000 mmFeeding system

Protowa automatic mixing stationPrinter weight

800 kgPersonnel per shift

3DrukMix L / DrukMix L+

Production of mixing and feeding of the mixture

up to 25 l/min (Recommended ~15 l/min for extruder Ex100 A)Allowed filler fraction «DrukMix L»/ «DrukMix L+»

up to 2mm / up to 5 mmSupport of mineral fillers (DrukMix L+)

YesDiameter of the feeding hose

DN35-50 mmMaximum length of the feeding track

up to 30 m (From the station to the extruder)Maximum height of the mixture lift

up to 3 mRecommended print speed

up to 200 mm/min (For stable feeding/layering)Power supply

380 V, 50 Hz (Standard industrial power supply)Consumed power of the complex

up to 12 kW (Total: station+feeding+control)Dimensions of the complex

~6,0 x 2,0 x 3,0 m (Total area and height of placement)Weight

~950 kgComponents of the complex

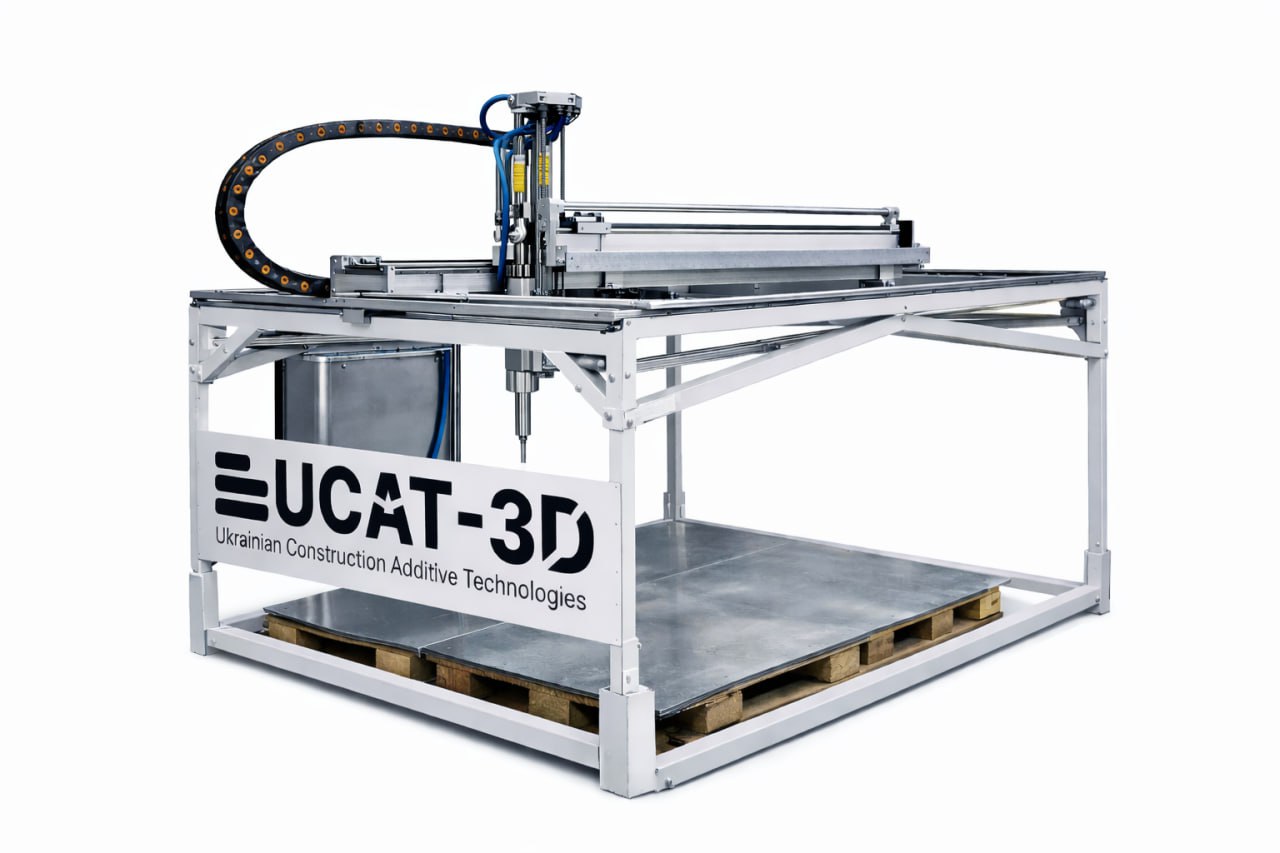

1) vibrating sieve; 2) discharger; 3) silo; 4) mixer; 5) filler addition doser; 6) pump for feeding the building mixture; 7) control system; 8) hoses and clamps; 9) printer reprogramming; 10) start-up and adjustment; 11) warranty serviceUCAT-3D Rebuild UA (M/S/L)

| Configurations | Print field | Dimensions |

|---|---|---|

| UCAT-3D Rebuild UA-L | 2400*1200*1000 mm | 3000*2000*1000 mm |

| UCAT-3D Rebuild UA-M | 1600*1200*1000 mm | 2000*2000*1000 mm |

| UCAT-3D Rebuild UA-S | 800*1200*1000 mm | 1000*2000*1000 mm |

Layer size (height x width)

5-25 mmx20-50mm (adjusted by speed and nozzles)Materials

cement, lime, clay and polymer mixtures, compatible with 3D-extrusionFile formats

G-code (.gcode, .gco) etc.Model preparation

foreign slicers (Cura, Slic3r or similar)Maximum printing speed

up to 12 m/minPositioning accuracy XY

±5 mmPositioning accuracy Z

±3 mmType of drive

stepping motorsPower supply

230 V, 50 HzConsumed power

5 kWClimatic conditions of operation

+10…+35 °C (in most cases depends on the characteristics of the building 3D mixture)Dimensions (LxWxH)

3700 x 2900 x 2400 mmWarranty

12 monthsEquipment

3D printer for working with building mixtures, built-in controller, basic ZIS, power cables, user manualThere may be other modifications of robotic equipment, in accordance with the solution of your tasks and technical tasks